Autonomous mobile robots , such as MOBOT ® AGV produced by WObit is a solution that enables the creation of safer and more efficient jobs. Let's take a look at the various security aspects associated with the use of these devices.

1. Relief from dangerous and non-ergonomic tasks

Due to the built-in security system, and the LMS laser navigation system AGV self-driving vehicles can independently and safely move in production and storage spaces.

Repeatedly and precisely transport various types of loads, relieving employees from non-ergonomic and repetitive tasks that are detrimental to their health. Such solutions as the load lifting system, automatic rollers or mandrels allow for independent picking and putting down of heavy pallets or elements directly from the production line. They can also move freely in rooms that are too loud or warm / cold for people.

2. User-friendly technology that meets stringent standards

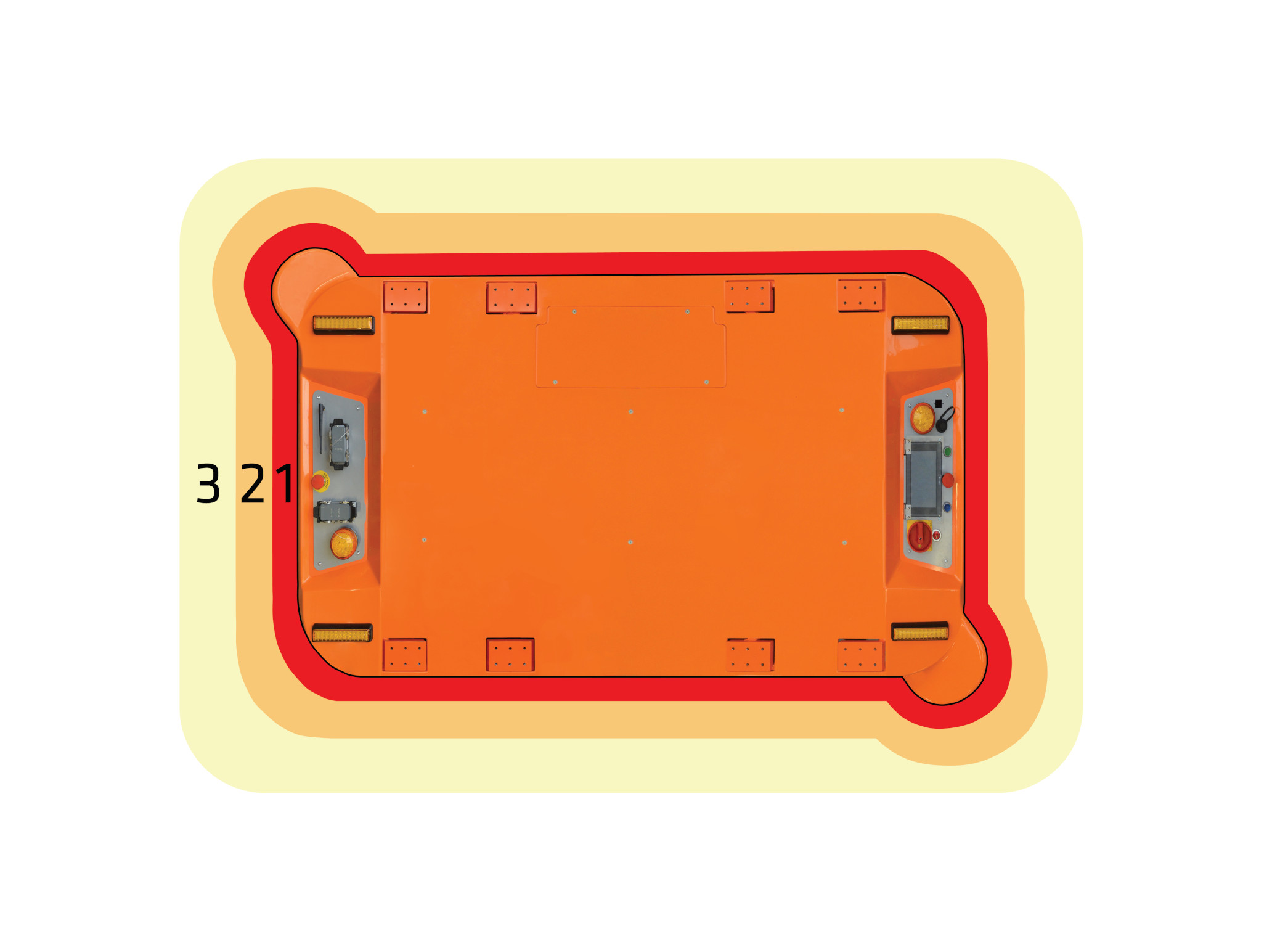

Mobile robots MOBOT ® are equipped with laser scanners with security function checking the space around AGV.

Let's see how it works on the example of the latest MOBOT® AGV FlatRunner MW Light . It has scanners placed on the diagonal of the device, thanks to which its field of view is 360 °. This allows the robot to respond appropriately when it encounters an obstacle, e.g. Mecanum wheels providing the device with the ability to move in any direction.

What's more, the robot detects people approaching from different sides safely working in a dynamic or changing environment. When they are too close, the AGV slows down, and the security system allows you to immediately stop in a certain zone, preventing a potential collision.

3. Agile and durable construction

The transport safety is also affected by the solid construction, ensuring reliable and repeatable transport of heavy loads. The streamlined composite housing in a bold orange color improves the robot's visibility. In the case of non-standard loads transported by AGV, the adapter adapted to the load can be retrofitted with additional sensors and security systems. It is also worth emphasizing the compact construction of robots, e.g. the CubeRunner , which allows agile movement in narrow passageways.

The aspect of the best interaction of the device with people and ensuring adequate communication is also important. That is why all MOBOTs are equipped with intuitive light and sound signaling. They communicate about various events by reproducing voice information and music.

4. Mobile robots for use in hazardous spaces

The industrial sector in the automotive, FMCG, logistics and electronics industries is increasingly investing in robotization and process automation. This is due to the need for cost optimization of work and operating costs. Companies are focused on increasing productivity and improving quality, security is also an important aspect. Investing in technology is increasingly also about implementing self-propelled mobile robots to automate in-house logistics. This is due to the important role of internal transport in the supply chain. The implementation of innovations such as mobile robots at this stage affects the functioning of the entire enterprise and allows gaining a competitive advantage.

The big advantage of autonomous transport vehicles from the safety point of view is their possibility of cooperation with other industrial machines and robots. Thanks to appropriate communication and good planning of processes, MOBOT® self-driving vehicles can, for example, enter production cells where industrial manipulators work and receive / deliver details to such positions. This ensures the safety of employees who do not need to interact directly with the machine, and also has a positive effect on process improvement, as there is no need to stop the work cycle of the manipulator.

5. Autonomous mobile robots in times of infection

In the face of a pandemic, two more security aspects are worth highlighting. The first is the obvious benefit associated with the implementation of cargo transport between different points in the company by robots instead of people. Reducing the need for employees to move between departments reduces the risk of transmission of bacteria and viruses within the plant , thus improving safety. Currently, AGV trolleys are often used in clean room applications, operating in areas with increased cleanliness requirements, e.g. in laboratories or special production zones.

Thanks to their flexible and compact design, mobile robots offer a wide range of applications not only in industry and logistics, but also in healthcare. It is an excellent tool to support hospital intralogistics and deliver e.g. bedding or meals in wards. An interesting example from recent weeks is the use of AGV robots for UV disinfection in Chinese hospitals.

Self-driving transport robots can be easily retrofitted with a variety of accessories that provide a wide range of applications, including tasks such as the example mentioned above. In relation to mobile robots MOBOT ® AGV, depending on the needs, they can be equipped with a roller conveyor, pallet truck, robotic arm, gravity conveyor or other solution adapted to the given application. About various modules and prams you can read more here .

If the article interested you and you are considering using mobile robots in your company, please contact our specialists .

Did you get interested in this article?

If you have any question contact our specialists.