There are many different vehicles available on the market for the automation of internal transport, which have similar functionalities, but are called differently. In this article, we explain what the individual names mean, where they come from and what are the most important differences in the technology in question, as well as what category the machines manufactured by WObit belong to.

Historical outline and taxonomy

AGV (automated guided vehicle), i.e. automatic trolleys, were introduced into use already in the 1950s. Initially, these were single implementations, mainly in the automotive area. Over time, they began to automate internal logistics in other industries as well.

As this technology developed, various types of vehicles appeared, differing in the way they pick up and transport cargo, as well as in their navigation methods.

The ISO 3691-4:2020 standard calls all powered vehicles intended for automatic cargo transportforklift trucks without an operator(driveless industrial truck). In the introduction to the standard you can read that this applies, among others, to: AGV, AMR, AGC (automated guided cart), tugger tunnel, under cart etc.

Alfredo Pastor Tella, author of "What the Heck is an Automated Guided Vehicle?: Cutting non value-added costs with Mobile Robots” przyjmuje, że wózki AGV stanowią podstawową technologię, z której wraz z rozwojem wyewoluowały różne typy urządzeń. Można by to porównać do języków, gdzie z języka indoeuropejskiego wykształciły się języki germańskie, słowiańskie czy romańskie. Dlatego wszystkie wózki jezdniowe bez operatora możemy nazwać AGV. Jednak, gdy chcemy dookreślić ich specyficzne właściwości, możemy zastosować dodatkowe nazewnictwo, które zostało wprowadzone przez producentów maszyn.

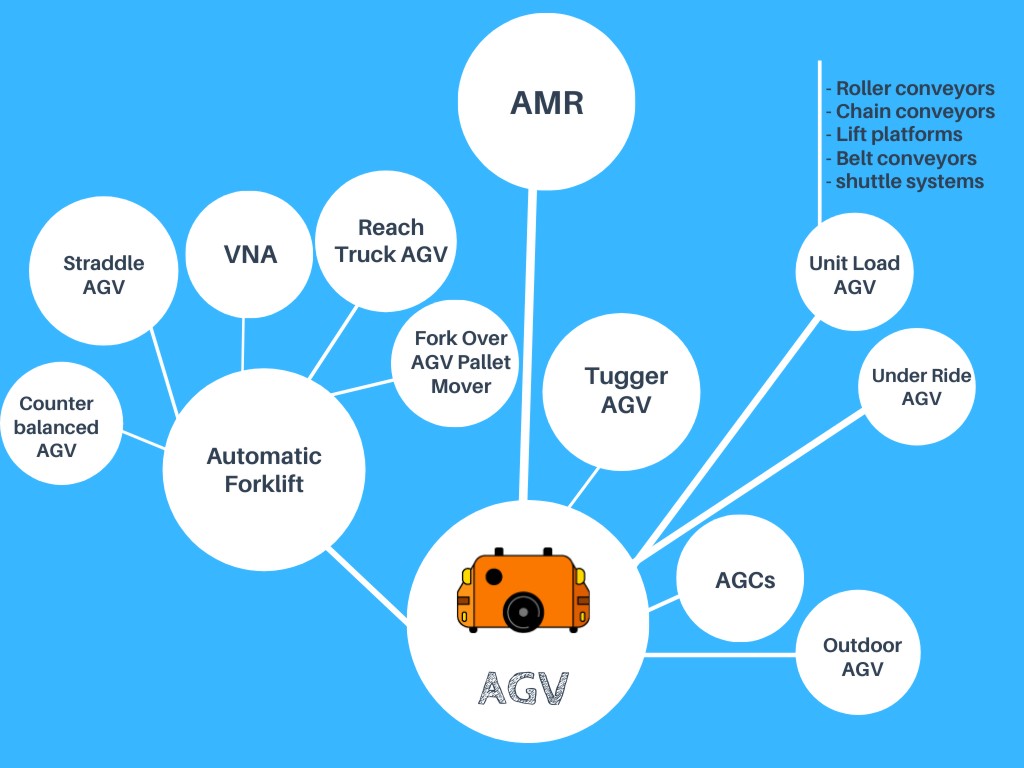

According to the taxonomy given by Alfredo Pastor Tell, the following types of machines that have developed within AGV can be distinguished:

Division by navigation methods

The taxonomy presented above shows a division according to the method of picking up and transporting the load, the place of use and the navigation method. It should be noted that the above names were created by machine manufacturers and were systematized by Alfredo Pastor Tella.

In the following, we will focus on the division according to navigation method, which results from the fact that vehicles with the so-called natural navigation, which does not require a physical transport path and moves along any route.

The most popular navigation methods are:

- Magnetic point navigation (small magnetic points embedded in the floor are used),

- Cable navigation - the oldest method requiring an electric wire embedded in the floor,

- Optical line navigation - following a colored tape or painted line on the floor, additionally marked with QR codes,

- Magnetic navigation - following a magnetic tape placed on the floor, often additionally marked with RFID tags,

- Laser navigation - using triangulation sensors directed to reflectors placed on the LGV (laser guided vehicle) route,

- Natural navigation - uses robot sensors such as 2D or 3D scanners to map space and create a virtual map. Natural navigation includes the SLAM, LIDAR and LMS methods.

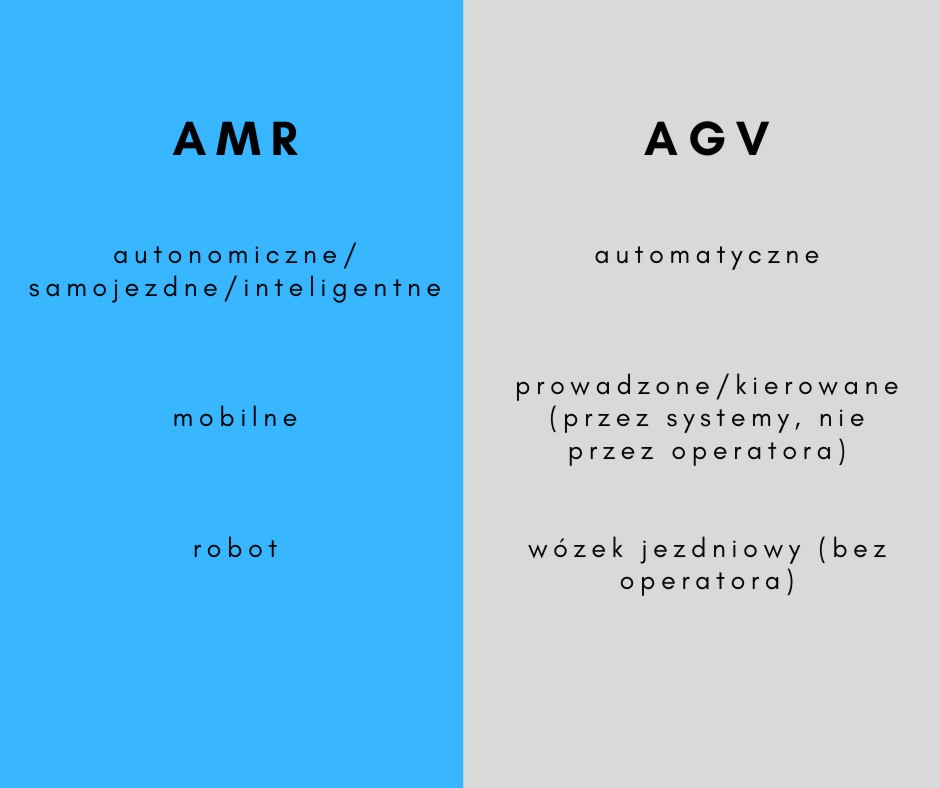

To simplify, all vehicles using navigation that requires physical route marking can be called AGV, while those using natural navigation - AMR.

Additionally, AMR vehicles are often calledintelligent. Warto zaznaczyć, że określenie intelligent, wcześniej zarezerwowane raczej dla ludzi, jednak obecnie coraz częściej stosowane w odniesieniu do urządzeń. Z łaciny słowo intelligentia oznacza zdolność pojmowania, rozumienie. W kontekście urządzeń mowa tu o urządzeniu elektronicznym, które zazwyczaj jest połączone z innymi urządzeniami i sieciami za pośrednictwem protokołów komunikacyjnych (zwykle bezprzewodowych) i może pracować w sposób interaktywny i autonomiczny (samodzielny).

At this point, the nomenclature regarding the AMR vehicles themselves should be further clarified, because around the same time, several manufacturers around the world introduced different names to describe the same type of machines, the most popular of which are AMR, SGV, SDV, AIV.

SGV – Self Guided Vehicle

SDV - Self Driving Vehicle

AIV – Autonomous Intelligent Vehicle (Autonomous Intelligent Trucks/Vehicles),

AMR – Autonomous Mobile Robot.

In terms of functionality, we can put an equal sign between them, so for simplicity, in the further part of the comparison we will consider the differences between AGV and AMR, in accordance with the standardization given above.

Comparison of AGV and AMR technologies

The most important characteristic features of AGV trolleys are:

NAVIGATION: It is done using a physical path made of magnetic tape/inductive loop or color line. Additionally, characteristic points are marked using RFID tags or QR codes.

IMPLEMENTATION: requires installation of navigation lines/points and additional markings.

FLEXIBILITY - changing the route requires changing navigation lines and additional markings.

RESPONSIVE – limited – the robot moves only along the designated route, and if it encounters an obstacle, it usually stops and waits for it to be removed.

The most important characteristics of AMR trolleys/robots are:

NAVIGATION: the device is equipped with 2D/3D scanners that create a map of the terrain, using only naturally occurring objects such as walls (that's why this method is sometimes called natural navigation). Having mapped the space and designated points for the robot to reach, it determines the optimal route.

IMPLEMENTATION: It is very quick, you need to map the surroundings, designate points (tasks) in the software between which the vehicle is to move and that's it.

FLEXIBILITY: The robot analyzes the changing environment and adapts to it, e.g. by avoiding obstacles and selecting the optimal route. Changing the tasks and points between which the vehicle is to move can be done very quickly by marking other points on the virtual map, there is no need to interfere with the physical space.

RESPONSIVE: The robot automatically identifies obstacles and avoids them (if space on the route allows it), and also selects the optimal route to the next point.

Robot vs. Cart/Vehicle

In the context of the machines discussed, the term trolley/vehicle or mobile robot also appears. All these names refer to a machine that transports loads from point A to B and is controlled using appropriate navigation systems without the need for direct operator support.

A robot according to the PN-EN ISO 8373:2001 standard is an automatically controlled, programmable, multi-task machine with many degrees of freedom, having manipulation or locomotion properties. Mobile robot defines a class of robot that can move using wheels or tracks.

The name mobile robot is sometimes used to distinguish between a machine and equipment in the form of a trailer, which is often called a trolley.

Security

In terms of safety, all types of driverless vehicles are subject to high requirements regulated by a number of standards. Both AGVs and AMRs are safe thanks to a complex system of sensors, vision systems and other equipment. In the case of AGVs, they move deterministically along a designated route. They are predictable for staff who know exactly where they will encounter machines and what their reaction will be. When an obstacle is encountered, these machines simply stop and wait for it to be cleared so they can continue working.

Vehicles classified as AMR are also equipped with a complex security system, as described in more detail in article on safety. In addition to avoiding collisions, these machines are much more flexible because they can change routes and avoid obstacles while moving in a dynamic, or changing, environment. For the people who work with them, they are more unpredictable, but they clearly inform the environment about the maneuvers being performed. This is achieved using light and sound messages generated by machines.

What applications are AGV and AMR suitable for?

In companies that rarely change in terms of products produced, workflow or workforce, AGV may be a good solution. For example, if on a production line that produces material placed in a box every 20 minutes, for 3 shifts a day - where the need is for the load to always be picked up from the same place and always delivered to the same machine, why more flexibility? In a situation where it is required to deliver a specific load from a designated point on the assembly line and this will not change in the next 5 years, it is better to use an AGV forklift.

However, if you are a manufacturer or manage a warehouse that experiences rapid changes in material flow, workstations or product mix, you need a more flexible solution that can change with you.

AMR vehicles are collaborative and flexible to keep up with future production and warehouse operations. They can avoid obstacles and relieve employees of repetitive or less ergonomic work, so they can focus on more valuable and satisfying tasks.

Most importantly, easy to set up and use, AMRs enable immediate return on investment. You can quickly deploy an autonomous mobile robot and adapt it to changing needs. Flexibility, advanced navigation and ease of implementation make AMR vehicles the ideal solution for automating dynamic operations and supporting a team of employees.

Profitability and costs

The analysis should also take into account the cost aspect. AGVs themselves are usually cheaper than AMR vehicles, but the cost of AGV implementation should include the cost of the color/magnetic line and QR codes that must be implemented. Installing AMR is usually faster and cheaper because it only requires mapping the surroundings. If transportation automation requires very long routes, with multiple destinations, or you need routes with multiple options, AMRs become more convenient compared to other technologies such as magnetic or laser navigation.

In the case of less complex installations, AMRs may prove to be more expensive, at least in the initial investment period. However, their other advantages, such as flexibility, can make it a more cost-effective solution.

A unique solution in this respect is new MOBOT® TRANSPORTER – an inexpensive AMR mobile robot manufactured by WObit. You can configure the machine yourself via the website, deciding on the functionality and the total cost, which is known immediately. Details here.

MOBOT®

MOBOT® vehicles manufactured by WObit are mostly machines that belong to the category AMR/AIV/SGVdue tothe natural laser navigation of the LMSwith which they navigate in space. The WObit company names them mobile robots and this name is used in the product description.

WObit's offer also includes vehicles navigated along a line using a vision system, which should be classified as AGV trolleys.

Summary

As you can see, a wide selection of vehicles for automating internal and external transport is currently available on the market. Answering the title question - the diversity of names results from their creation by different AGV/AMR manufacturers and is primarily of a marketing nature, the aim of which is to increase product sales.

Which machine is right for your application? It depends on your needs and goals that you want to achieve thanks to robotization. Contact us todayto learn more about how easy to use, industrially durable and designed for immediate operation < strong>MOBOT® mobile robotsmay be suitable for your application.

Did you get interested in this article?

If you have any question contact our specialists.