Internal transport of cargo is an important process in the supply chain, but it does not bring added value in itself. It is a necessary expense. For this reason, and also due to the growing need for optimization and the shortage of qualified employees, this process is more and more often automated by means of, inter alia, autonomous mobile robots .

What if, however, add value to the transport processes?

In this article, we will show you how, using automatic transport , you can use the travel time to perform additional tasks - in this case quality control of the detail.

The application in question was presented during the Modernlog 2021 fair in Poznań. For the transport of cargo in the presented task, MOBOT® AGV CubeRunner2 mobile robot with a load capacity of up to 200 kg. The robot is equipped with an electrically powered belt feeder, powered by the robot's batteries. This feeder enables automatic picking up and depositing of loads from loading and unloading points, e.g. from other stationary feeders.

Two optoNCDT 1900 triangulation laser sensors with a measuring range up to 25 mm. Series of sensors optoNCDT 190 0 produced by Micro-Epsilon is characterized by high precision - linearity up to 1 µm, repeatability <0.1 µm, adjustable measurement frequency up to 10 kHz and a very compact design. The largest measuring range available is 500 mm. The innovative sensor is predestined for displacement, distance and position measurements in the automation, automotive, rail, robotics, 3D printing and coordinate measuring machines.

Thanks to the Advanced Surface Compensation function, measurements are just as reliable regardless of the surface, from shiny metal to multi-colored, from light to dark, matt to shiny. The small measuring spot enables precise detection of even the smallest parts, and the compact and robust design allows mounting on the robot. There is one more function worth paying attention to, which is very useful in the discussed application, which is two-stage averaging in order to optimize the signal. High-performance averaging enables a precise signal waveform, especially important for high-speed measurements of moving parts.

Mentioned sensors optoNCDT 1900 were mounted precisely opposite to each other, so that using the principle of differential measurement to be able to verify the width of the detail.

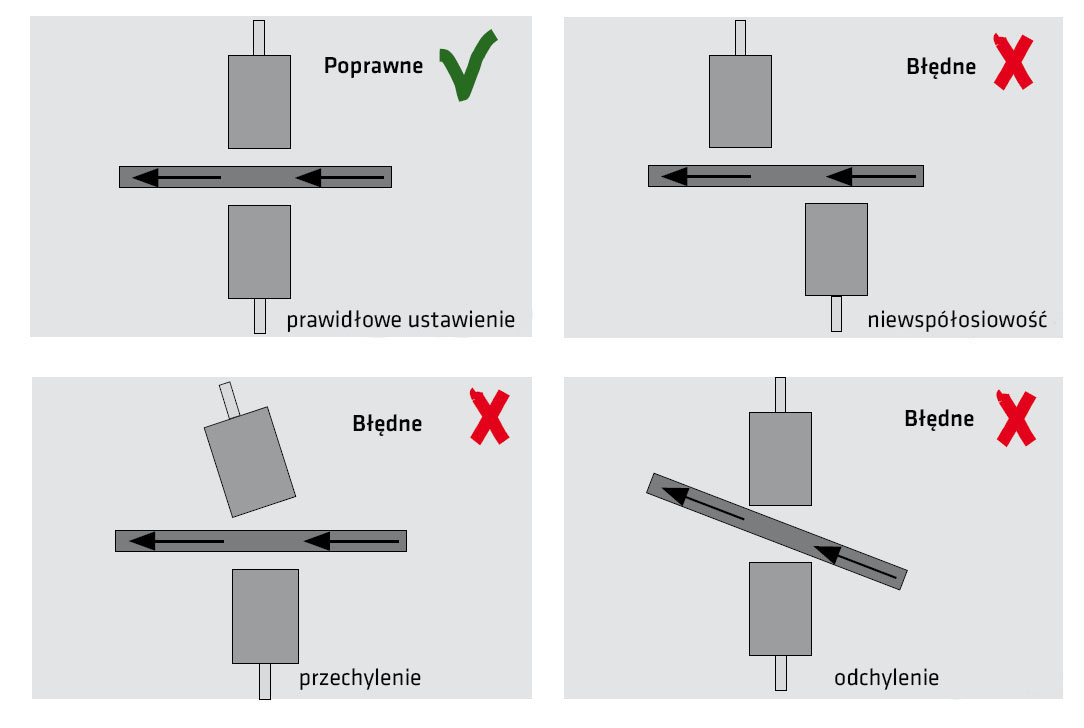

Displacement triangulation sensors measure distance, movement and dimensions. If the measured values of the two displacement sensors are evaluated together, the thickness / width of the object can be determined on this basis. However, to get an accurate target width determination from the combined signals of the two sensors, care must be taken to properly mount and align the sensors. synchronization is also extremely important when measuring an object that is moving.

To avoid disturbance caused by the movement of the measured objects, both sensors must be synchronized so as to measure at the same time at exactly the opposite point of the object. If synchronization does not occur, faulty measurement data is generated. For example, micro-vibrations of a measured object may occur if the measurements are taken at different times, resulting in an error. In order to ensure proper synchronization in the discussed application, the C-Box / 2A controller was used, which enables the connection of 2 triangulation sensors simultaneously. As a result, the synchronization of two measurements is carried out at exactly the same time. The output obtains a width measurement from the configurable analog output.

Then the data from the analog output is processed by ADAE42-ETH measurement module . This universal module allows for independent measurement from 4 analog channels, it is equipped with a measurement averaging function, it also has mathematical functions implemented, enabling operation on measured values from analog channels. The information is then sent to the integrated HMI panel where the data is displayed in real time. In this application, 3 details are measured, each with different dimensions and a different material, i.e. a shiny metal detail, a plastic detail printed by a 3D printer and a wood detail (organic material).

The visualization of the measurement has been prepared on the panel and at the time of measurement for each type of detail, information about the actual width of the detail (in mm) is displayed. In addition, a three-color light column has been integrated on the robot, which informs about the correctness - compliance of the detail with the pattern or non-compliance - non-compliance with quality standards. The advanced surface compensation function ensures precise and repeatable measurements regardless of the material of the detail.

The application presented above is an example of the fact that the moment of transporting details, especially between subsequent stages of the production cycle, can be used to perform additional tasks, such as quality control. By equipping the mobile robot with additional sensors or measuring systems, there is additional space for process optimization.

Will this solution work for you? Would you like to learn more about transport automation or measurement? Contact WObit specialists .

Did you get interested in this article?

If you have any question contact our specialists.